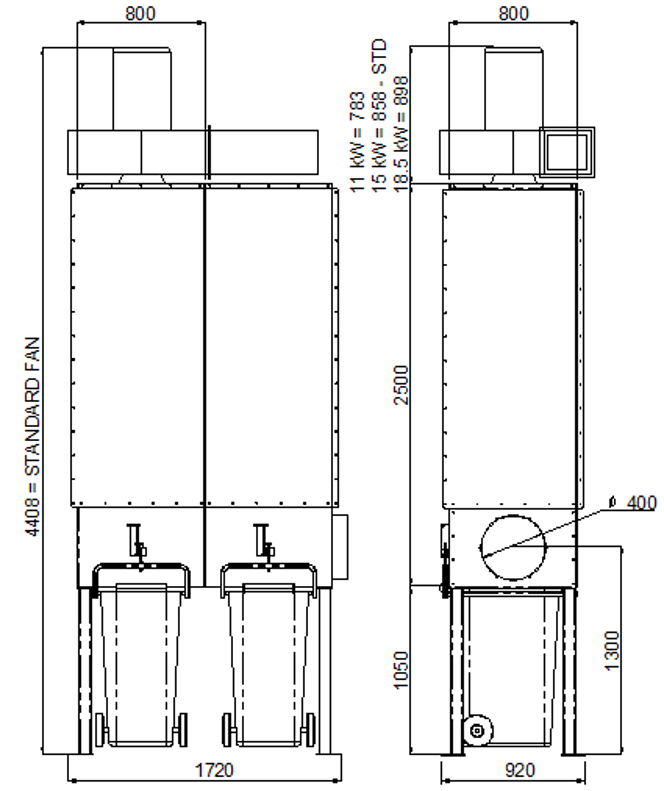

VC 8s

INTRODUCTORY PARAGRAPH

Key Features and Benefits Quick Summary

Big Performance, Small Package: the VC 8s with top-mounted fan occupies less than two square metres of floor space with a low profile for applications with limited roof height, while offering the capacity and performance of a much larger dust extractor. For extremely low rooves,

Negative Pressure Collector: no dust spewing out onto your shop floor.

Clean Air Fan: protects the fan from abrasive/ impact damage and reduces energy costs.

Automatic Filter Cleaning: its powerful shaker motor and frame clean all the filters after every use.

Fast, Ergonomic Dust Disposal: “Quick-lock” bin system eliminates lifting, spillage and alignment issues.

Designed and Made in Australia: engineered to perform and built to last!

Technical Data:

Construction:

- Powder-coated, laser cut, 3mm thick galvanized steel sheet carcass

- Fully welded, hot-dipped galvanized steel legs, from 5mm angle iron

- One adjustable leg, 250mm range of adjustment

- Fully sealed and assembled using stainless steel fittings

Filters:

- 8 washable, spun-bond polyester cartridge filters, encased in rugged perforated metal cylinders to ensure effective vibration transfer to the entire filter and to protect the filter from impact damage.

- 323mm Ø x 850mm long, with 99.5% filtration efficiency at 1 micron. Total filter surface area = 68 m2

- 10mm separation between pleats for optimal dust release during cleaning cycle.

- PTFE filters also available

Filter Chamber:

- Dirty air enters below the filters into a pre-separation dirty air plenum that separates heavier waste from fine dust. The heavier waste drops into collection bins. The fine dust spirals over the filters.

- The filter chamber is negatively pressurised to ensure air is drawn in (as opposed to being blown-in when the chamber is under pressure). The negatively pressurised filter chamber ensures that dust sealing is 100%. Should a void in the seal occur, air will be drawn from the atmosphere into the unit, no dust will be expelled into the work environment.

Inlet:

- Integrated Galvanised steel spigot,

- Standard diameter (mm): 400 nominal (other inlet sizes, types available on request)

- Location: dirty air plenum, left, or right side of plenum, rear side as an optional extra

Wheelie Bin:

- 2 Heavy duty, high impact, 240 litre capacity, with 14 kg total mass minimum

- Quick-lock lever release and replace system

- Bins can be used with or without bin liners

Shaker motor specifications: